Can desalination quench agriculture’s thirst?

Miles away from the ocean, projects are afoot to clean up salty groundwater and use it to grow crops. Some say it’s a costly pipe dream, others say it’s part of the future.

Support sound science and smart stories

Help us make scientific knowledge accessible to all

Donate today

Ralph Loya was pretty sure he was going to lose the corn. His farm had been scorched by El Paso’s hottest-ever June and second-hottest August; the West Texas county saw 53 days soar over 100 degrees Fahrenheit in the summer of 2024. The region was also experiencing an ongoing drought, which meant that crops on Loya’s eight-plus acres of melons, okra, cucumbers and other produce had to be watered more often than normal.

Loya had been irrigating his corn with somewhat salty, or brackish, water pumped from his well, as much as the salt-sensitive crop could tolerate. It wasn’t enough, and the municipal water was expensive; he was using it in moderation and the corn ears were desiccating where they stood.

Ensuring the survival of agriculture under an increasingly erratic climate is approaching a crisis in the sere and sweltering Western and Southwestern United States, an area that supplies much of our beef and dairy, alfalfa, tree nuts and produce. Contending with too little water to support their plants and animals, farmers have tilled under crops, pulled out trees, fallowed fields and sold off herds. They’ve also used drip irrigation to inject smaller doses of water closer to a plant’s roots, and installed sensors in soil that tell more precisely when and how much to water.

In the last five years, researchers have begun to puzzle out how brackish water, pulled from underground aquifers, might be de-salted cheaply enough to offer farmers another water resilience tool. Loya’s property, which draws its slightly salty water from the Hueco Bolson aquifer, is about to become a pilot site to test how efficiently desalinated groundwater can be used to grow crops in otherwise water-scarce places.

Desalination renders salty water less so. It’s usually applied to water sucked from the ocean, generally in arid lands with few options; some Gulf, African and island countries rely heavily or entirely on desalinated seawater. Inland desalination happens away from coasts, with aquifer waters that are brackish — containing between 1,000 and 10,000 milligrams of salt per liter, versus around 35,000 milligrams per liter for seawater. Texas has more than three dozen centralized brackish groundwater desalination plants, California more than 20.

Such technology has long been considered too costly for farming. Some experts still think it’s a pipe dream. “We see it as a nice solution that’s appropriate in some contexts, but for agriculture it’s hard to justify, frankly,” says Brad Franklin, an agricultural and environmental economist at the Public Policy Institute of California. Desalting an acre-foot (almost 326,000 gallons) of brackish groundwater for crops now costs about $800, while farmers can pay a lot less — as little as $3 an acre-foot for some senior rights holders in some places — for fresh municipal water. As a result, desalination has largely been reserved to make liquid that’s fit for people to drink. In some instances, too, inland desalination can be environmentally risky, endangering nearby plants and animals and reducing stream flows.

But the US Bureau of Reclamation, along with a research operation called the National Alliance for Water Innovation (NAWI) that’s been granted $185 million from the Department of Energy, have recently invested in projects that could turn that paradigm on its head. Recognizing the urgent need for fresh water for farms — which in the US are mostly inland — combined with the ample if salty water beneath our feet, these entities have funded projects that could help advance small, decentralized desalination systems that can be placed right on farms where they’re needed. Loya’s is one of them.

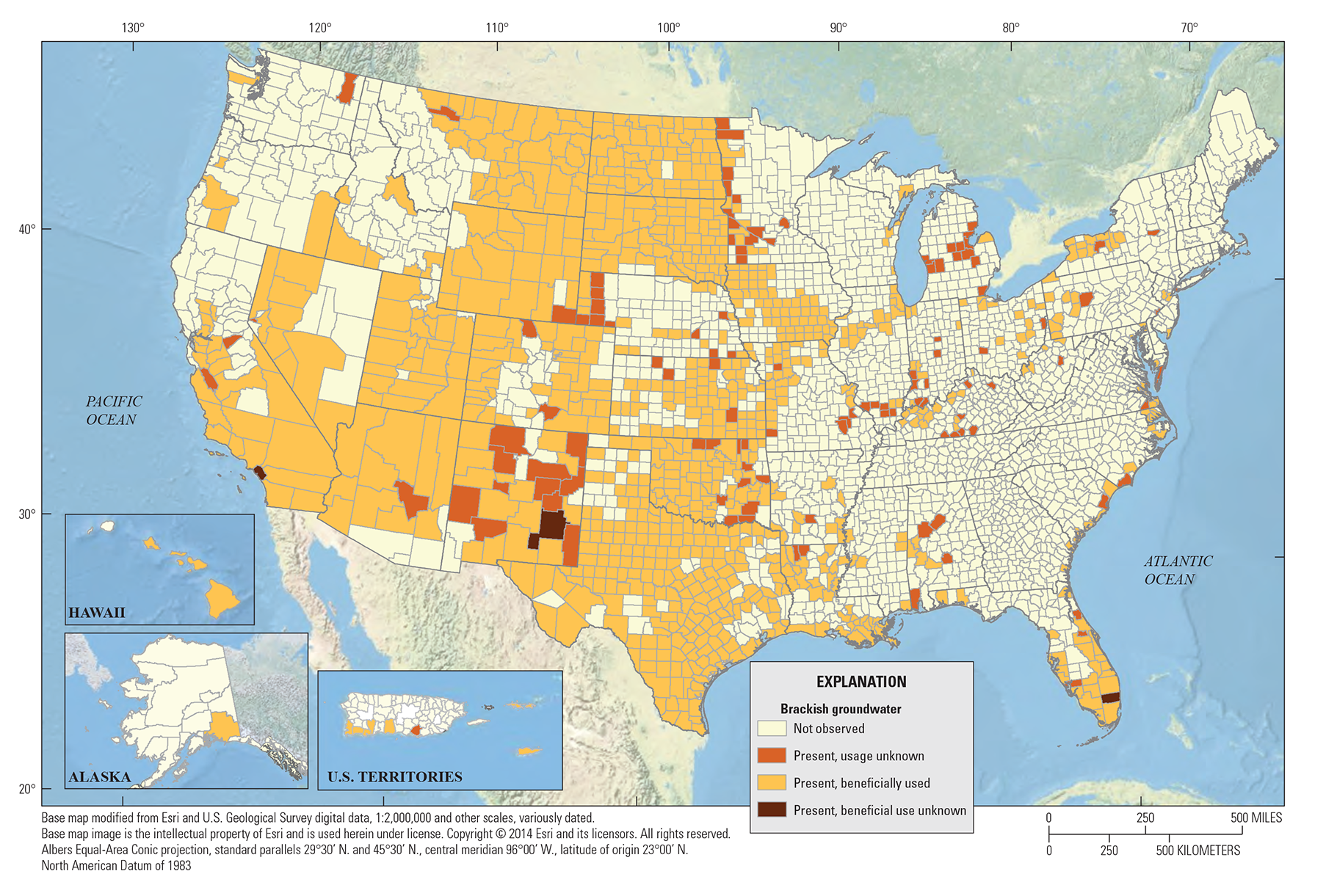

US farms consume over 83 million acre-feet (more than 27 trillion gallons) of irrigation water every year — the second most water-intensive industry in the country, after thermoelectric power. Not all aquifers are brackish, but most that are exist in the country’s West, and they’re usually more saline the deeper you dig. With fresh water everywhere in the world becoming saltier due to human activity, “we have to solve inland desal for ag … in order to grow as much food as we need,” says Susan Amrose, a research scientist at MIT who studies inland desalination in the Middle East and North Africa.

Brackish (slightly salty) groundwater is found mostly in the Western United States.

CREDIT: J.S. STANTON ET AL / BRACKISH GROUNDWATER IN THE UNITED STATES: USGS PROFESSIONAL PAPER 1833. 2017

That means lowering energy and other operational costs; making systems simple for farmers to run; and figuring out how to slash residual brine, which requires disposal and is considered the process’s “Achilles’ heel,” according to one researcher.

The last half-decade of scientific tinkering is now yielding tangible results, says Peter Fiske, NAWI’s executive director. “We think we have a clear line of sight for agricultural-quality water.”

Swallowing the high cost

Fiske believes farm-based mini-plants can be cost-effective for producing high-value crops like broccoli, berries and nuts, some of which need a lot of irrigation. That $800 per acre-foot has been achieved by cutting energy use, reducing brine and revolutionizing certain parts and materials. It’s still expensive but arguably worth it for a farmer growing almonds or pistachios in California — as opposed to farmers growing lesser-value commodity crops like wheat and soybeans, for whom desalination will likely never prove affordable. As a nut farmer, “I would sign up to 800 bucks per acre-foot of water till the cows come home,” Fiske says.

Loya’s pilot is being built with Bureau of Reclamation funding and will use a common process called reverse osmosis. Pressure pushes salty water through a semi-permeable membrane; fresh water comes out the other side, leaving salts behind as concentrated brine. Loya figures he can make good money using desalinated water to grow not just fussy corn, but even fussier grapes he might be able to sell at a premium to local wineries.

Such a tiny system shares some of the problems of its large-scale cousins — chiefly, brine disposal. El Paso, for example, boasts the biggest inland desalination plant in the world, which makes 27.5 million gallons of fresh drinking water a day. There, every gallon of brackish water gets split into two streams: fresh water and residual brine, at a ratio of 83 percent to 17 percent. Since there’s no ocean to dump brine into, as with seawater desalination, this plant injects it into deep, porous rock formations — a process too pricey and complicated for farmers.

Rows of reverse osmosis membranes at the Kay Bailey Hutchison Desalination Plant in El Paso.

CREDIT: PHOTO BY ADA COWAN

But what if desalination could create 90 or 95 percent fresh water and 5 to 10 percent brine? What if you could get 100 percent fresh water, with just a bag of dry salts leftover? Handling those solids is a lot safer and easier, “because super-salty water brine is really corrosive … so you have to truck it around in stainless steel trucks,” Fiske says.

Finally, what if those salts could be broken into components — lithium, essential for batteries; magnesium, used to create alloys; gypsum, turned into drywall; as well as gold, platinum and other rare-earth elements that can be sold to manufacturers? Already, the El Paso plant participates in “mining” gypsum and hydrochloric acid for industrial customers.

Loya’s brine will be piped into an evaporation pond. Eventually, he’ll have to pay to landfill the dried-out solids, says Quantum Wei, founder and CEO of Harmony Desalting, which is building Loya’s plant. There are other expenses: drilling a well (Loya, fortuitously, already has one to serve the project); building the physical plant; and supplying the electricity to pump water up day after day. These are bitter financial pills for a farmer. “We’re not getting rich; by no means,” Loya says.

More cost comes from the desalination itself. The energy needed for reverse osmosis is a lot, and the saltier the water, the higher the need. Additionally, the membranes that catch salt are gossamer-thin, and all that pressure destroys them; they also get gunked up and need to be treated with chemicals.

Reverse osmosis presents another problem for farmers. It doesn’t just remove salt ions from water but the ions of beneficial minerals, too, such as calcium, magnesium and sulfate. According to Amrose, this means farmers have to add fertilizer or mix in pretreated water to replace essential ions that the process took out.

To circumvent such challenges, one NAWI-funded team is experimenting with ultra-high-pressure membranes, fashioned out of stiffer plastic, that can withstand a much harder push. The results so far look “quite encouraging,” Fiske says. Another is looking into a system in which a chemical solvent dropped into water isolates the salt without a membrane, like the polymer inside a diaper absorbs urine. The solvent, in this case the common food-processing compound dimethyl ether, would be used over and over to avoid potentially toxic waste. It has proved cheap enough to be considered for agricultural use.

Amrose is testing a system that uses electrodialysis instead of reverse osmosis. This sends a steady surge of voltage across water to pull salt ions through an alternating stack of positively charged and negatively charged membranes. Explains Amrose, “You get the negative ions going toward their respective electrode until they can’t pass through the membranes and get stuck,” and the same happens with the positive ions. The process gets much higher fresh water recovery in small systems than reverse osmosis, and is twice as energy efficient at lower salinities. The membranes last longer, too — 10 years versus three to five years, Amrose says — and can allow essential minerals to pass through.

Data-based design

At Loya’s farm, Wei paces the property on a sweltering summer morning with a local engineering company he’s tapped to design the brine storage pond. Loya is anxious that the pond be as small as possible to keep arable land in production; Wei is more concerned that it be big and deep enough. To factor this, he’ll look at average weather conditions since 1954 as well as worst-case data from the last 25 years pertaining to monthly evaporation and rainfall rates. He’ll also divide the space into two sections so one can be cleaned while the other is in use. Loya’s pond will likely be one-tenth of an acre, dug three to six feet deep.

From left, West Texas farmer Ralph Loya, Quantum Wei of Harmony Desalting and engineer Johanes Makahaube discuss where a desalination plant and brine pond might be placed on Loya’s farm.

CREDIT: PHOTO BY ADA COWAN

The desalination plant will pair reverse osmosis membranes with a “batch” process, pushing water through multiple times instead of once and gradually amping up the pressure. Regular reverse osmosis is energy-intensive because it constantly applies the highest pressures, Wei says, but Harmony’s process saves energy by using lower pressures to start with. A backwash between cycles prevents scaling by dissolving mineral crystals and washing them away. “You really get the benefit of the farmer not having to deal with dosing chemicals or replacing membranes,” Wei says. “Our goal is to make it as painless as possible.”

Another Harmony innovation concentrates leftover brine by running it through a nanofiltration membrane in their batch system; such membranes are usually used to pretreat water to cut back on scaling or to recover minerals, but Wei believes his system is the first to combine them with batch reverse osmosis. “That’s what’s really going to slash brine volumes,” he says. The whole system will be hooked up to solar panels, keeping Loya’s energy off-grid and essentially free. If all goes to plan, the system will be operational by early 2025 and produce seven gallons of fresh water a minute during the strongest sun of the day, with a goal of 90 to 95 percent fresh water recovery. Any water not immediately used for irrigation will be stored in a tank.

Spreading out the research

Ninety-eight miles north of Loya’s farm, along a dead flat and endlessly beige expanse of road that skirts the White Sands Missile Range, more desalination projects burble away at the Brackish Groundwater National Desalination Research Facility in Alamogordo, New Mexico. The facility, run by the Bureau of Reclamation, offers scientists a lab and four wells of differing salinities to fiddle with.

On some parched acreage at the foot of the Sacramento Mountains, a longstanding farming pilot project bakes in relentless sunlight. After some preemptive words about the three brine ponds on the property — “They have an interesting smell, in between zoo and ocean” — facility manager Malynda Cappelle drives a golf cart full of visitors past solar arrays and water tanks to a fenced-in parcel of dust and plants. Here, since 2019, a team from the University of North Texas, New Mexico State University and Colorado State University has tested sunflowers, fava beans and, currently, 16 plots of pinto beans. Some plots are bare dirt; others are topped with compost that boosts nutrients, keeps soil moist and provides a salt barrier. Some plots are drip-irrigated with brackish water straight from a well; some get a desalinated/brackish water mix.

A brine pond at the Brackish Groundwater National Desalination Research Facility in Alamogordo, New Mexico.

CREDIT: PHOTO BY ADA COWAN

Eyeballing the plots even from a distance, the plants in the freshest-water plots look large and healthy. But those with compost are almost as vigorous, even when irrigated with brackish water. This could have significant implications for cash-conscious farmers. “Maybe we do a lesser level of desalination, more blending, and this will reduce the cost,” says Cappelle.

Pei Xu, has been co-investigator on this project since its start. She’s also the progenitor of a NAWI-funded pilot at the El Paso desalination plant. Later in the day, in a high-ceilinged space next to the plant’s treatment room, she shows off its consequential bits. Like Amrose’s system, hers uses electrodialysis. In this instance, though, Xu is aiming to squeeze a bit of additional fresh — at least freshish — water from the plant’s leftover brine. With suitably low levels of salinity, the plant could pipe it to farmers through the county’s existing canal system, turning a waste product into a valuable resource.

Xu’s pinto bean and El Paso work, and Amrose’s in the Middle East, are all relevant to Harmony’s pilot and future projects. “Ideally we can improve desalination to the point where it’s an option which is seriously considered,” Wei says. “But more importantly, I think our role now and in the future is as water stewards — to work with each farm to understand their situation and then to recommend their best path forward … whether or not desalting is involved.”

Sixteen plots of pinto beans at the Brackish Groundwater National Desalination Research Facility are being irrigated with water of differing salinities, as part of an experiment.

CREDIT: PHOTO BY ADA COWAN

Indeed, as water scarcity becomes ever more acute, desalination advances will help agriculture only so much; even researchers who’ve devoted years to solving its challenges say it’s no panacea. “What we're trying to do is deliver as much water as cheaply as possible, but that doesn't really encourage smart water use,” says NAWI’s Fiske. “In some cases, it encourages even the reverse. Why are we growing alfalfa in the middle of the desert?”

Franklin, of the California policy institute, highlights another extreme: Twenty-one of the state’s groundwater basins are already critically depleted, some due to agricultural overdrafting. Pumping brackish aquifers for desalination could aggravate environmental risks.

There are an array of measures, say researchers, that farmers themselves must take in order to survive, with rainwater capture and the fixing of leaky infrastructure at the top of the list. “Desalination is not the best, only or first solution,” Wei says. But he believes that when used wisely in tandem with other smart partial fixes, it could prevent some of the worst water-related catastrophes for our food system.

10.1146/knowable-112124-3

TAKE A DEEPER DIVE | Explore Related Scholarly Articles